A blade is said to be ultrasonic when an electronic system is connected to it which makes it vibrate vertically between twenty and thirty-five thousand times per second, yes, it is really per second which gives it very interesting cutting properties because they are modular. The characteristics of the vibration are controlled by a generator and a transmitter connected to the blade.

To be convinced, it is enough to activate the vibration or not and the difference is immediate the cut begins from the contact in the product without compressing it and is carried out without any resistance to the vibrations transmitted to the blade.

This is why the limits of a classic blade are very quickly exceeded in terms of:

- Very fast cadence and speed,

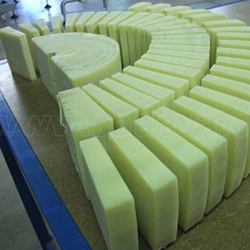

- No deformation of products,

- Fineness of the slices which can be very thin,

- The formats obtained can be smaller such as sweets or chocolates

- Cutting becomes industrial and repeatable,

- There is no gluing of the products on the blade,

- There is no brake that is to say loss of product by crumbs, the product opens without loss of material,

- The cut is clean and appetizing

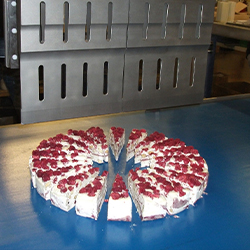

- Blades can cut pies or baking sheets in molds

- The vibrations are adapted to the density and controlled according to the products by allowing the cutting of frozen or variable products of multiple compositions. We cut artichokes in pâtés for example.

Why an ultrasonic cutting machine?

Sodeva manufactures its own electronic systems and vibrating blades. We conduct comparative trials to select the best profile. We have our showroom to carry out the tests without going to the fairs where cuts are not allowed. Our customers come from far away to check the cutting qualities as our Indian customers who have a complete cutting production line from Paneer.

A machine is equipped with one or more blades chained in different cutting stations to achieve the final result.

We manufacture blades more than one meter long if necessary in one piece to cut large blocks of cheese or small scarification blades for buns before cooking.

A machine can integrate weighing, 3D or Rx vision, spacer removal, check weighers and packaging solutions. We cut chocolate plates on sheets of paper that then allow a very easy coating, for small or large volumes.

The weights at the output of machines are said to be fixed or regular and are very precise to the gram which induces a quick return on investment.

The total automatic washing of the blades is also possible to avoid cross-contamination of nuts or others.

A machine is standard or tailor-made according to the needs of our customers.

Ultrasonic cutting solutions

- Our equipment is prepared with control softwares to know the performance and outputs of the machines, between the weights entered and sold at the end of the line

- The recipes are saved according to the adjustment steps of our customers' teams.

- The packaging machines are controlled by our PLC if necessary.

- Works in tandem with all your current conveyor systems or other power-related equipment.

What to remember from ultrasonic cutting?

To increase productivity and process control, study our industrial ultrasonic slicers with innovations that have changed markets and provided major competitive advantages in recent years.

Do not hesitate to contact us and test your products if you want the best returns on investment.